How HPP Works

High Pressure Processing systems employ pressures to inactive many food borne pathogens such as Salmonella, E coli and Listeria, with no change in organoleptic properties or nutritional value

HPP works because uniform high pressure affects microbial cellular integrity and metabolism without affecting the covalent structures of food components responsible for nutrition (structural proteins, fibers, fats, enzymes etc.).

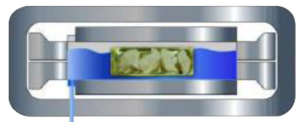

1. Product Loading

2. Vessel Pre-Filling

3. Pressurizing

4. Product Unloading

Once the cell wall is fractured

within 24 36 hours, the natural acidic properties of the product then inactivate the pathogens. Specific pressure and hold times are carefully monitored to ensure HPP does not affect the good bacteria.

Molecular bonds are not broken during HPP, and as a result, no free radicals or chemical by products are formed. The duration of the pressurization phase (generally two to three minutes) determines the efficacy of pathogen inactivation. The HPP process does not affect the structural integrity of the package used, as the pressure is simultaneously applied uniformly on the food and the package

A Closer Look at the HPP Process

Using our state of the art equipment, there is no difference in color or texture. Other companies may use inferior ingredients, older less accurate processors, or improper care during the HPP process, which can result in rubbery texture, color changes and sticking to chub film. We do not see any of these concerns with any of the brands and products we produce using our HPP apparatus. While other processors may use different equipment, pressure, hold times and not use chilled water, MMI/PSI consistently combines the correct factors when using HPP. This is absolutely crucial for producing a true raw food. With ongoing research, education and testing, MMI/PSI can assure you that all products from our facility will have the highest quality, bio available nutrition

available.

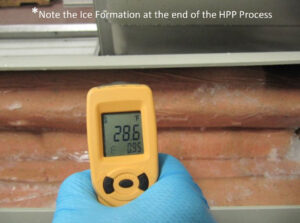

Entering the Process

Product temperature prior to entering the chamber is 29˚F

Exiting the Process

Product temperature upon completion 28.6˚F. Temperature drops due to the rapid decompression.

All Natural Process

HPP Advantages

- Offers manufacturers of raw food diets/products a non thermal process to insure pathogen inactivation.

- 5 log reduction achieved at 87,000 psi inactivating pathogens salmonella, E. coli and Listeria.

- Eliminates the need for chemical additives, irradiation, heat applied methods (steam) or additives of any kind.

- Attractive for consumers Meets the demand for safe raw pet food products through non thermal processing.

- Permits the inactivation of microorganisms at low temperatures, while valuable nutritional components such as proteins, fats, vitamins, minerals, enzymes and beneficial bacteria remain unaffected.

Clean. Natural. Efficient.

Pressure Safe is working continually to close the loop and off-set not only our carbon footprint, but that of our community.